Waste becomes valuable fuel for bioethanol plants with our briquette press. In collaboration with an experienced partner, we have developed a technology, which makes straw material useful in briquettes for bioethanol plants.

In bioethanol plants, the key is the pre-treatment process, making the handling of raw material and the introduction of biofuel into the ethanol plants much simpler while also reducing investments and costs. At C.F. Nielsen, we have specialized in delivering briquette presses that allows you to turn waste into resources for a cost-effective and sustainable production.

The concept for bioethanol is a patented 2nd generation technology using straw as raw material for briquette pressing. The briquetted straw has a high absorption rate – 7-10 times more than normal straw.

Straw is often considered as waste material in agricultural production. However, the 2nd generation technology transforms by-products into valuable fuel using briquetted straw in a bioethanol plant. Different systems have been used in other 2nd generation with little success. Briquetting proves to be the ideal solution being a cheaper and less complex process.

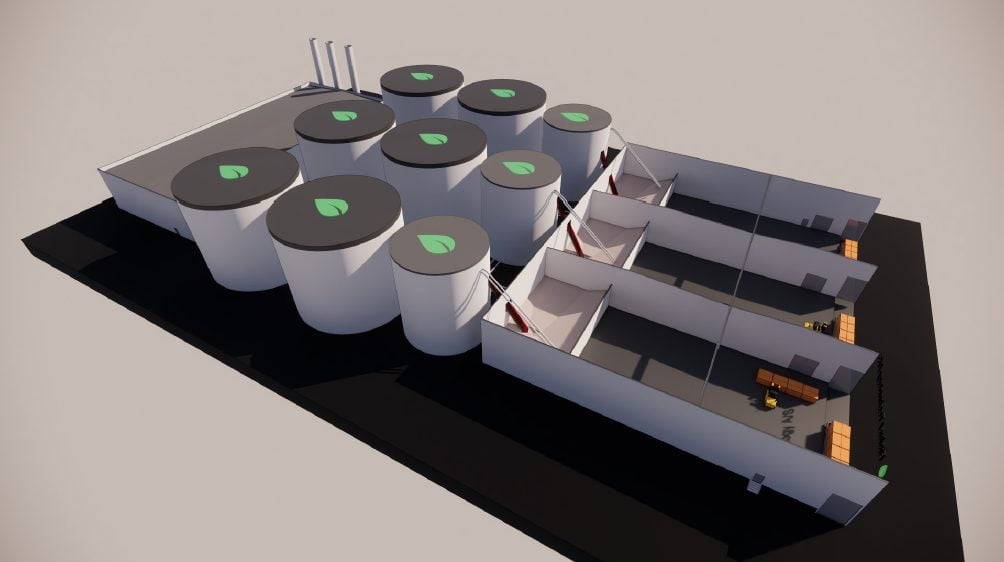

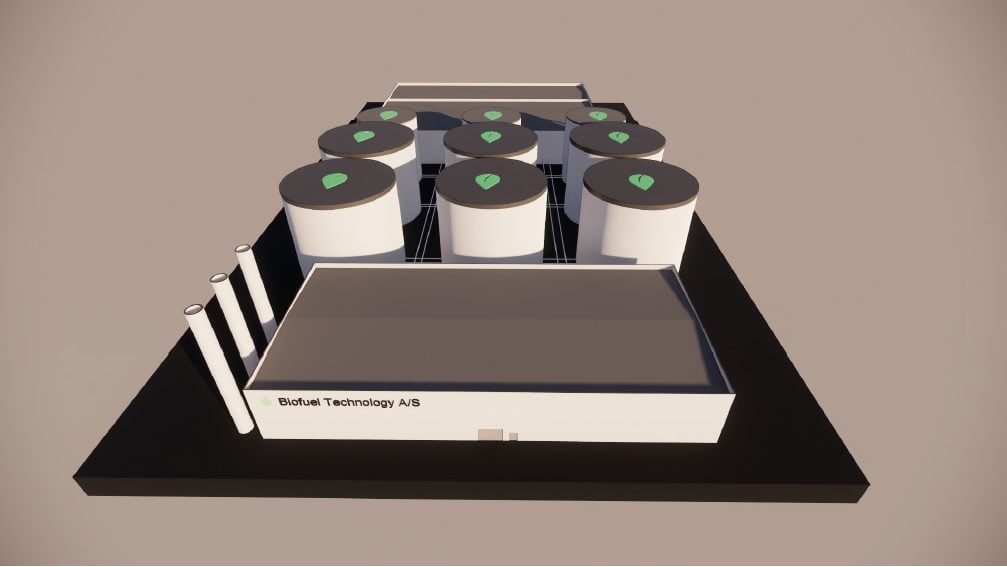

We can deliver a complete briquette press system for briquetting straw. The press can be delivered including handling equipment, complete with shredding and milling equipment, including sand and stone removal, and high capacity mechanical presses. Line capacities start at 500 kg per hour and can produce up to 20 tonnes per hour.

The briquetting pretreatment technology is considerably cheaper than other alternatives. The briquette press for bioethanol combines a logistical system for transportation of straw - a simple pre-treatment system that reduces the complexity of the ethanol process. As a result of the briquetting process, a small steam explosion is created and the cell structure is opened giving easier access to beneficial bacteria making it easier to disperse the straw briquettes in biofuel reactors.

The large mechanical presses BP6510 and BP7510 hold the capacities of 1,5 and 2,75 tonnes per hour of briquetted straw, respectively. The mechanical briquette presses are piston and flywheel based presses that operate with 270 revolutions per minute. The machine creates pressure beyond 2000 kg/m2, which increases the necessary small steam explosions that change the structure of the straw, making the whole pre-treatment of the straw simpler than other alternatives.

Due to the reduced complexity of the ethanol process, the investment in the plant will be reduced considerably, because a part of the pre-treatment happens during the briquetting process. As a result of the reduced capex costs, the opex costs will be reduced as well.

The briquetting process covers all principal steps, including the mechanical pre-treatment of the straw, the actual briquetting, the final thermochemical steam pre-treatment before the ethanol process, including the enzymatic liquidation, fermentation, and distillation, and final liquid separation. Producing biogas on the stillage is an integral part of biofuel production and the final liquid separation.

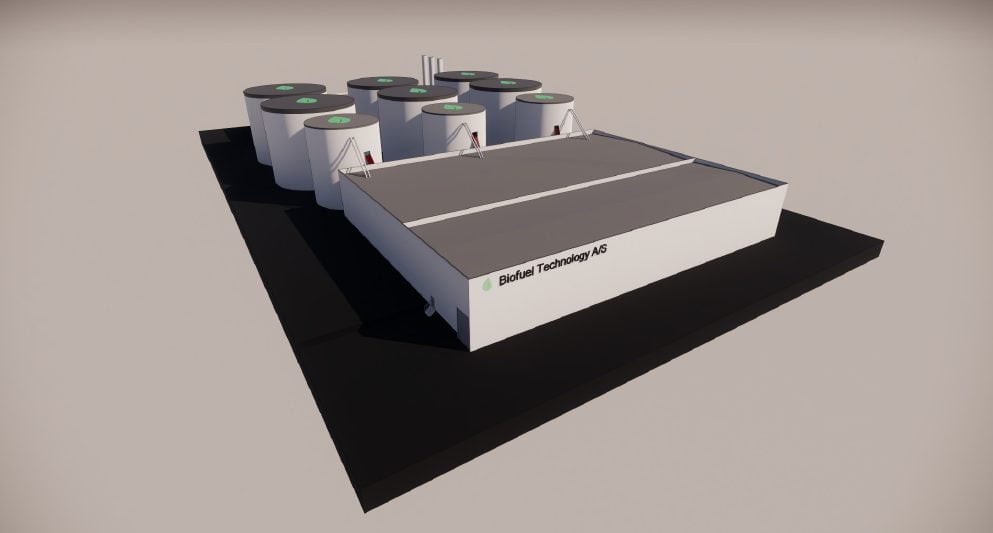

The system is marketed by our partner Biofuel Technology A/S under the trademark CELLEBRIQTM – an acronym for CELLlulosic Ethanol from BRIQettes.

Contact us to know more about our adaptable solutions.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.