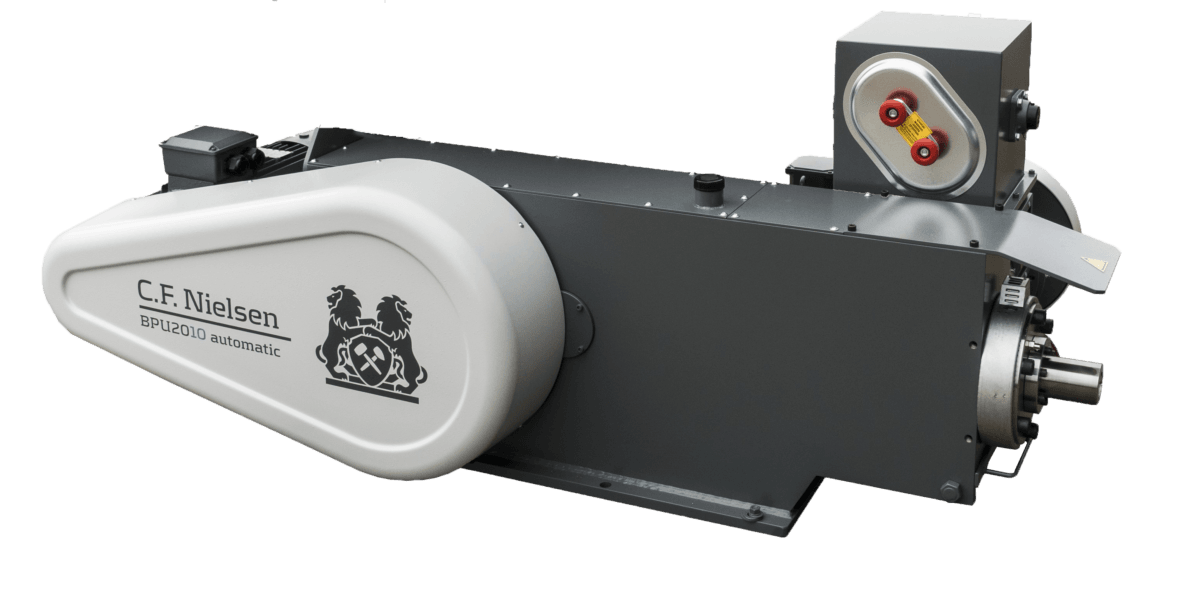

The BP2010 and BP2510 models are the latest upgrade and our smallest mechanical presses. The presses are designed to meet the requirement industrial companies with smaller volumes, but also for organizations and companies in regions like Africa, that require a strong and reliable briquetting press.

The BP2010 and BP2510 can be supplied with separate dosing silo and as well as the BPU2010 and BPU2510, which are compact units with a small dosing silo attached, fully cabled and ready to go.

The presses are well suited for the production of briquettes of many different agricultural and wood based raw material including dust like MDF. The presses are strong and reliable mechanical presses designed for automatic 3-shift operation. All vital parts are integrated in the strong machine frame and glass fiber protective housing.

The briquettes can typically be used as industrial briquettes for boilers in district heating or power plants, but also for other purposes such as briquettes for cooking stoves in regions like Africa.

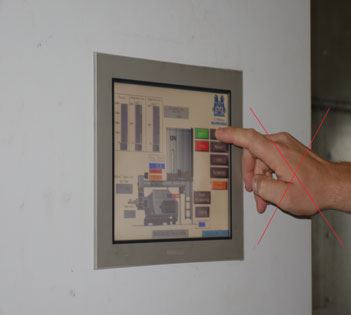

The control systems can either be delivered as relay-based or with PLC. The relay-based option will mainly be delivered to installations where the operations are not fully automatic. The PLC based systems comes with Siemens PLC for automatic operation and the functional BBCS, Basic Briquetting Control System

including a 5.7” multi-color monitor with user-friendly touch screen operation. It is possible to monitor, operate or search for failures and even to reprogram the PLC-function via an internet connection.

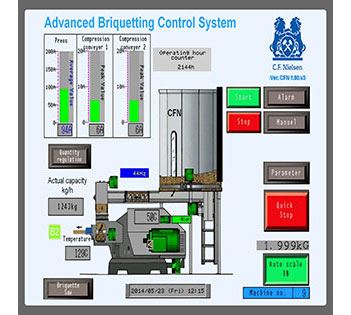

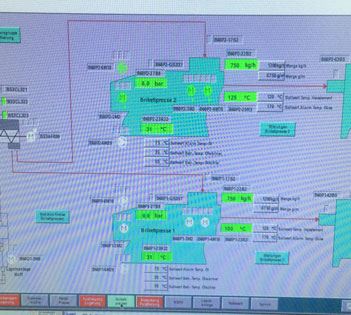

ABCS = Advanced Briquetting Control System - Recommended for consumer lines with saw. Operator interface is through a 10.4" touch screen display, with multi-level access control, to ensure that the right parameters are accessible to the right user. The ABCS has a highly graphical user interface, enabled by the large screen. The system includes many special features, and is the sum of CFN´s decades of experience in briquetting. Recommended for consumer briquetting lines.

BBCS = Basic Briquetting Control System - Recommended for industrial briquetting lines. Operator interface is through a 5.7" touch screen display, with multi-level access control, to ensure that the right parameters are accessible to the right user. The system includes many special features, and is the sum of CFN´s decades of experience in briquetting.

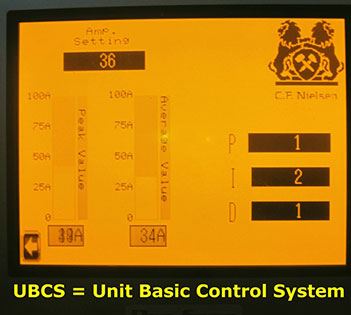

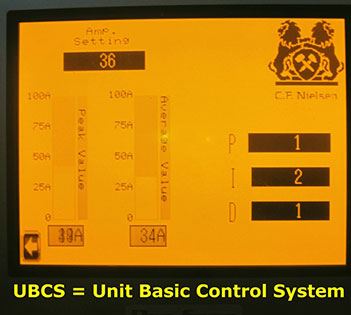

UBCS - Unit Briquetting Control System - for very simple briquetting operations.

Access includes a special VPN-module, which automatically establishes a connection to our service department, based on either a LAN cable, Wi-Fi signal or 3G USB stick (whichever is available on site). Not available for UBCS.

The control system can be connected to a SCADA system. A standard data-set with details on operation, is made available for pick-up in a data field in the Siemens PLC. Not available for UBCS.

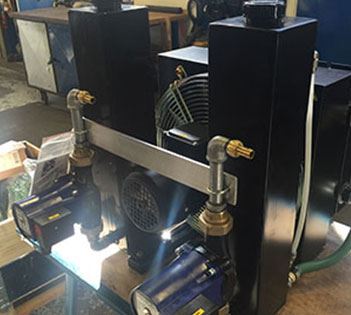

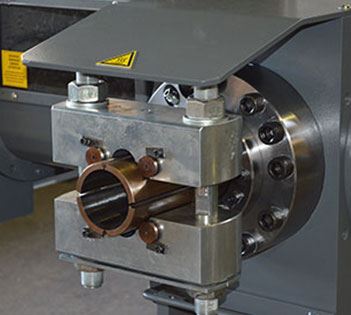

Oil cooling unit is recommended for all models, and especially for operation in + 45 degr. ambient temperatures and in rooms with lack of ventilation. Will increase lifetime and reduce maintenance costs.

Oil and PLC warming unit is needed if temperatures gets below 15+ degr. C.

For hardwood- and consumer briquettes/logs and for pressing abrasive raw material like straw and MDF. The die temperature is thermostatically controlled, based on user set point.

Mixer type 200 - for one press (BP2000-BP4000) including sub frame. For mixing water or any additives with the raw material prior to pressing. Often used for adding and mixing water with MDF and other low-moisture raw materials.

Water supply for mixer - to increase moisture content in dry material.

Cooling lines route the briquettes from the press to the designated storage area, or to the next machine in the process (for instance a briquette saw), while allowing the briquette string to cool under pressure. For industrial lines, a minimum length of 15 meters is reccomended, while 30 meters is recommended for consumer lines. Maximum length is around 50 meters. Bends with radius 1.5 or 3 m. can be incorporated in the design.

Cover for cooling lines (for outdoor use only). Protects the briquettes against rain and snow. Easy to install, tarp-based construction, fixed with stainless steel clips.

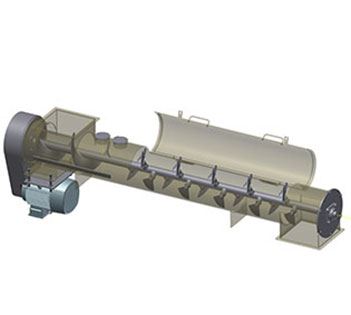

Frequency controlled dosing screws for extra presses (L= max 2,5m).

Level sensors - for mounting in the dosing silo or larger storage silo. The sensors are a rotary type, which gives potential free signals. Needed in connection with automatic start/stop function of the press. We also offer an ultrasound type as alternative.

Switch track 1-3 lines. This is a manually operated switch system that allows you to direct the briquettes to up to 3 different locations. The press needs to be temporarily stopped or idled for shifting from one track to the other.

The function will start and stop the press depending on raw material availability and is ideal for industrial plants with limited silo capacity. The function is also needed for remote start/stop of a connected saw.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.