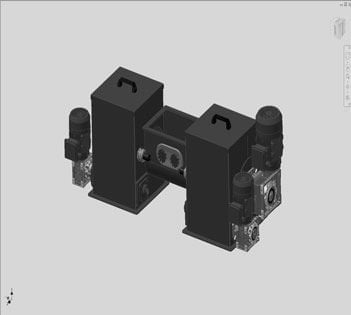

The mechanical briquetting press BP7010 has an advanced design and is the top line in briquetting. The double feeding system guarantees high capacity, regardless of the density of the raw material. The press is equipped with an advanced control system that allows internet access. It is possible to monitor, operate or search for failures and even to reprogram the PLC-function via an internet connection. All operation texts and failure notices can be shown in up to 16 languages. The log function is an important tool for analyzing and improving the briquetting process.

The BP 7010 is an extremely strong press with heavy bronze bearings and a sturdy housing made of high tensile steel and fixed on heavy steel reinforced concrete foundation which secures a quiet and safe operation with extremely low vibration level.

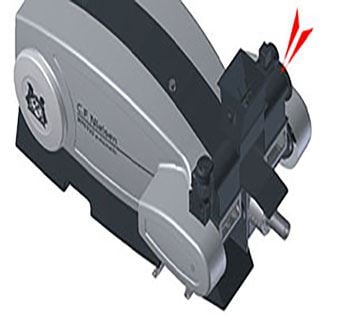

A unique piston and die system with exchangeable piston crown and wear rings is available for different types of briquettes from various raw materials.

The press is mainly suitable for high capacity production of consumer briquettes with a high density with a10-12% moisture and a capacity of up to 1700 kg/h. Briquettes can be round with a diameter of up to 100 mm or square 85×85 mm.

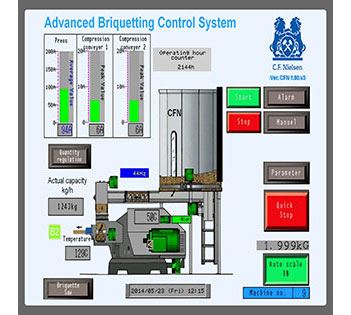

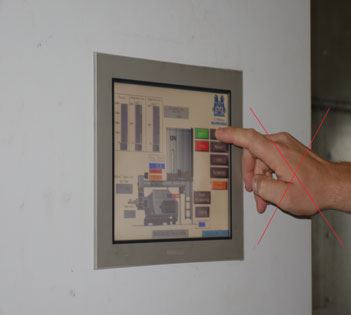

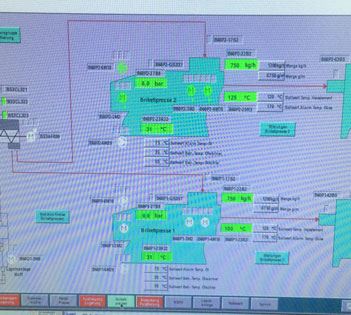

ABCS = Advanced Briquetting Control System - Recommended for consumer lines with saw. Operator interface is through a 10.4" touch screen display, with multi-level access control, to ensure that the right parameters are accessible to the right user. The ABCS has a highly graphical user interface, enabled by the large screen. The system includes many special features, and is the sum of CFN´s decades of experience in briquetting. Recommended for consumer briquetting lines.

Agitator for mixing of lignin or other additives with the raw material prior to entering the press. Perfect for mixing lignin with pine shavings and chips.

Will maintain the set capacity within +/- 50 kg per hour, even with fluctuating density of the raw material. Normally used to achieve high quality, consumer briquettes.

Will maximize capacity within set limits for power consumption of the press, even with fluctuating density of the raw material. Normally used to achieve high capacity, when making industrial briquettes.

The function will start and stop the press depending on raw material availability and is ideal for industrial plants with limited silo capacity. The function is also needed for remote start/stop of a connected saw.

BBCS = Basic Briquetting Control System - Recommended for industrial briquetting lines. Operator interface is through a 5.7" touch screen display, with multi-level access control, to ensure that the right parameters are accessible to the right user. The system includes many special features, and is the sum of CFN´s decades of experience in briquetting.

Bio-Start - grain feeding system .Feeds grain into the raw material just before the press is stopped. Makes the subsequent cold start easier, and reduces the load on all vital parts of the press. Recommended for production of square briquettes and briquettes with center hole. The system consists of two grain containers placed above each compression screw of the press.

For a few seconds, prior to final stop of the press, grain is fed into the raw material, in order to fill the die with a mix of grain and raw material. Since grain will not harden, the next cold-start will be easier on the machine.

Briquette Divider - For production of short briquettes with a length of 25-75 mm.

Cooling lines route the briquettes from the press to the designated storage area, or to the next machine in the process (for instance a briquette saw), while allowing the briquette string to cool under pressure. For industrial lines, a minimum length of 15 meters is reccomended, while 30 meters is recommended for consumer lines. Maximum length is around 50 meters. Bends with radius 1.5 or 3 m. can be incorporated in the design.

Cover for cooling lines (for outdoor use only). Protects the briquettes against rain and snow. Easy to install, tarp-based construction, fixed with stainless steel clips.

The control system can be connected to a SCADA system. A standard data-set with details on operation, is made available for pick-up in a data field in the Siemens PLC. Not available for UBCS.

For hardwood- and consumer briquettes/logs and for pressing abrasive raw material like straw and MDF. The die temperature is thermostatically controlled, based on user set point.

Discharge system for silo max Ø 8 m and max H = 13 m. (max 2 presses).

Enlarged inlet chamber for comp. screws (for straw and other voluminous products). Includes extra sensors in the precompression chamber.

Improves the feeding of the press to optimize capacity and reduce the risk of overfeeding.

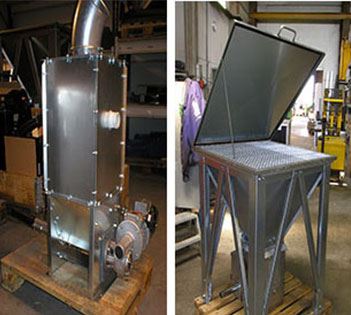

Equipment for active cooling of the briquettes in the cooling lines, further reduce the temperature of the briquette before it exits. (To approx. 20 deg. C) Normally used when a 30 meter cooling line is not achievable, in a consumer line.

Equipment for production of Ø90 briquettes with center hole. Will produce a draft hole with app. Ø20 mm diameter in the core of the briquette. Estimated lifetime for the pin is 400 - 1500 hours depending on the raw material.

We recommend this option only for consumer briquettes. The option always has to be combined with bio-start equipment.

Frequency controlled dosing screws for extra presses (L= max 2,5m).

Level sensors - for mounting in the dosing silo or larger storage silo. The sensors are a rotary type, which gives potential free signals. Needed in connection with automatic start/stop function of the press. We also offer an ultrasound type as alternative.

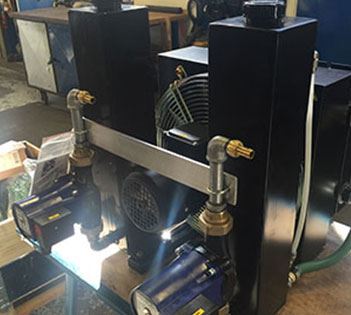

Lignin dosing unit for 1 press only. incl. reservoir - depending on test. For adding lignin or other additives to the raw material to improve on the quality of the briquettes. Also ideal for adding limestone to straw briquettes in combination with a mixer. Often used with pine for production of consumer briquettes.

Lignin dosing unit incl. reservoir and distribution system - depending on test. For adding lignin or other additives to the raw material to improve on the quality of the briquettes. Also ideal for adding limestone to straw briquettes in combination with a mixer. Often used with pine for production of consumer briquettes.

Loading line for 6 big-bags - including sensors for automatic filling of each bag.

Mechanical "Puck-maker" for short industrial briquettes (L = 10-30mm). The puck-maker is a mechanical device that is normally installed at the end of the cooling lines.

It is recommended to install a clip-slide after the puck-maker.

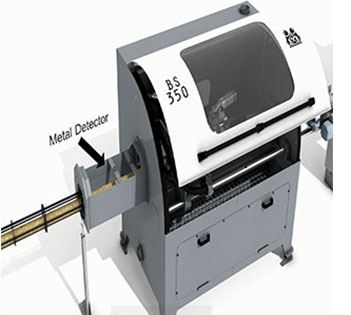

Metal detector - to be used in combination with BS350 saw + center hole. Will stop the press before a worn-out pin or other metal part gets hit by the saw blade.

Mixer type 600 - for one press (BP7010-BP7510) or two presses (BP5000-BP6510) including sub frames. For mixing water or any additives with the raw material prior to pressing. Often used for adding and mixing water with MDF and other low-moisture raw materials.

Oil and PLC warming unit is needed if temperatures gets below 15+ degr. C.

Oil cooling unit is recommended for all models, and especially for operation in + 45 degr. ambient temperatures and in rooms with lack of ventilation. Will increase lifetime and reduce maintenance costs.

Pneumatic briquette breaker with adjustable length - Length from 15 mm.

Access includes a special VPN-module, which automatically establishes a connection to our service department, based on either a LAN cable, Wi-Fi signal or 3G USB stick (whichever is available on site). Not available for UBCS.

SMS-Info (text message system) for failure alarm. Enables the machine to send a text message to an operator on call, in case of production stop.

Switch track 1-3 lines. This is a manually operated switch system that allows you to direct the briquettes to up to 3 different locations. The press needs to be temporarily stopped or idled for shifting from one track to the other.

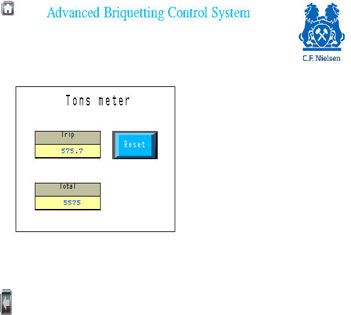

Registers the accumulated no. of ton produced. The counter can be reset by the operator.

Water supply for mixer - to increase moisture content in dry material.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.