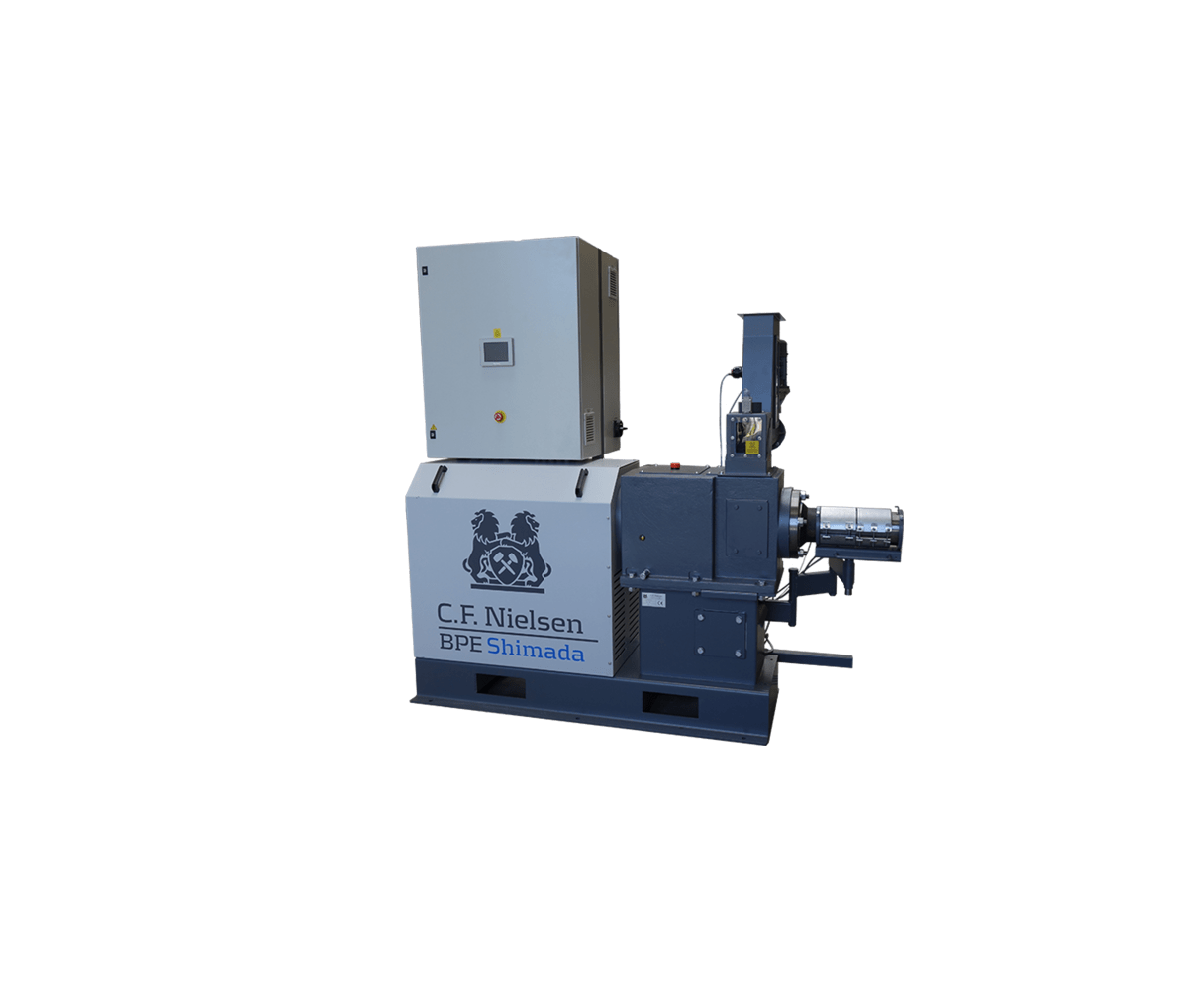

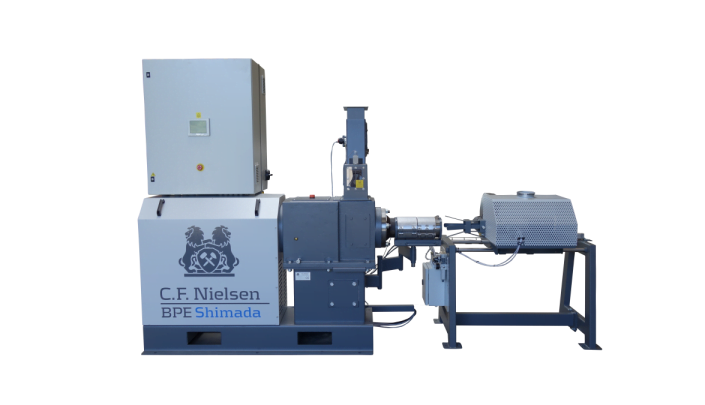

C.F. Nielsen now offers the new BPE Shimada Extruder Briquetting Press to complement the product range of mechanical briquetting presses. The press is equipped with an advanced control system that allows internet access. It is possible to monitor, operate or search for failures and even to reprogram the PLC-function via an internet connection. All operation texts and failure notices can be shown in up to 16 languages. The log function is an important tool for analyzing and improving the briquetting process. Relay based control panel can be delivered as an alternative.

The BPE Shimada Extruder Briquetting Press is sold for medium sized professional users and most types of wood and agricultural based raw materials can be used without adding a binder. The briquettes are typically used as consumer briquettes/logs for fireplaces and wood burning stoves. The briquettes are normally produced in a size of 62×62 mm with a length of 200 mm. Other sizes are optional.

Download the BPE Shimada Extruder Briquetting Press brochure.

The BPE SHIMADA is a briquetting press specialized to produce very dense biomass briquettes, which can be carbonized and sold as high quality carbonized briquettes.

In order to produce a good briquette on the BPE Shimada Briquetting Press you will need a moisture content of 6-8% and particles between 2-6 mm.

The Press is mounted on base frame with 45 Kw motor and drive assembly and includes a 1.1kw automatic screw feeder with variable speed control and Electrical Control panel and locking spanner. All fully pre-wired and test run prior to shipment. The press is delivered with an interconnecting smoke hood and a saw. Other options are available.

The dies and the tooling include Press Pipe Heat Tube, 3 Bushes (Taper Tungsten, SUS and FCD Tempered), Change Guide Pipe, Fixed Guide Pipe, Negative Taper Screw, Positive Screw, Draw Rod, Washers, and 2 Electric Ceramic Heater Bands.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.