Consumer wood briquettes are the ideal products for replacing traditional firewood. Since the end of the 90’s, the demand for consumer wood briquettes used for home heating systems, fireplaces and wood burning stoves have increased. Driven by the global focus on renewable energy, this demand is still growing. Compared to alternatives, briquettes are both convenient, profitable and sustainable.

With our briquetting machines, your waste will be turned into valuable renewable energy. In collaboration with our sister company RUF Briquetting System, we offer a wide range of customized solutions and a full line of consumer briquetting machines varying from low to very high capacities.

At C.F. Nielsen, we have specialized in mechanical briquetting. We offer high capacity lines ranging from 4-500 kg/hour and upwards, corresponding to wood waste of approximately 1.000 tonnes per year and more.

For consumer briquettes we offer everything from semi-structural economic solutions to high capacity briquetting machines. With the capacity of 4-500 kg/hour, the specialized extrusion briquette machines produce very high-density briquettes.

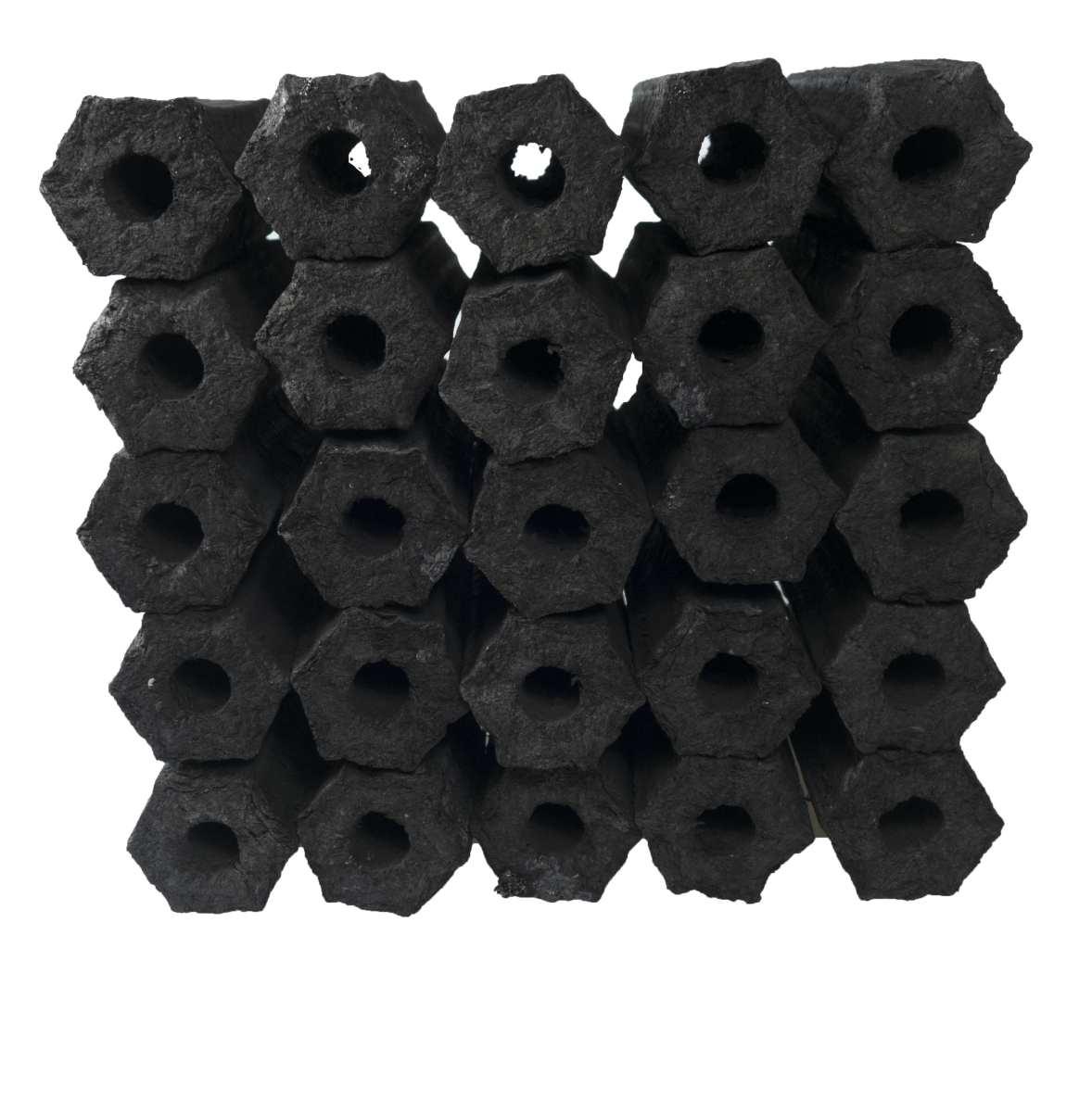

The high-density briquettes ensure longer burning time, ideal for customers with special requirements and needs for long lasting energy. The price for these briquettes are higher than other types, however, the superior quality and longevity matches the price. The logs are produced in sizes of 65x65x200 mm for biomass and 55x55x200 mm for carbonization.

Our BPE Shimada extrusion press is a strong and compact press, combined with our small BS250 Saw. The concept can be delivered as a single unit with a small buffer silo, dosing screw and touch screen panel. The extrusion system generates very strong and high-density briquettes, which are delivered in one entire piece.

We offer total line concepts, including the processes of downsizing, drying and briquetting. Producing extruded briquettes requires moisture levels of 4-8%. Obtaining these levels requires an efficient drying system. We can provide a full line concept through CFN Engineering consisting of everything required, including chippers, hammer mills, drying systems, filter systems, silos and buffer systems, conveyors and handling systems etc.

The combination of very high-density and the extrusion briquetting technology that binds the briquette, makes the briquettes ideal for carbonization. We have access to carbonization technology through our partners. We have our own testing kiln for carbonized briquettes. During customer visits, we can produce briquettes and carbonize them for testing and showcases. For this solution, the complete systems are organized in collaboration with our partners.

Download our White Paper on Carbonization here.

Are consumer briquettes the ideal match for your company? Or do you need more details on how our customized briquetting machines can turn your waste into renewable energy? Please contact us for any further information.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.