Within briquetting, difficult waste can be used for gasification. Some of our first briquetting plants were delivered to produce industrial fuel for boilers. Among these some have been operating for more than 30 years. In more recent times, the gasification solution has spread to other regions such as Eastern Europe, Africa, and Asia, where it is being used with local raw material – mainly agriculturally based.

Over the years, the briquette presses have been upgraded. Today, they include the latest technology resulting in higher capacities and lower costs per tonne produced. At C.F. Nielsen, we hold the knowledge and machinery to solve issues regarding transforming difficult material into briquettes that can be used for gasification.

Download our White paper on gasification here.

Many biomass by-products, such as dust and smaller particles including many types of agricultural raw materials cannot be used in a gasifier. However, by processing the raw material into high density briquettes, it is possible to use the raw material as valuable fuel.

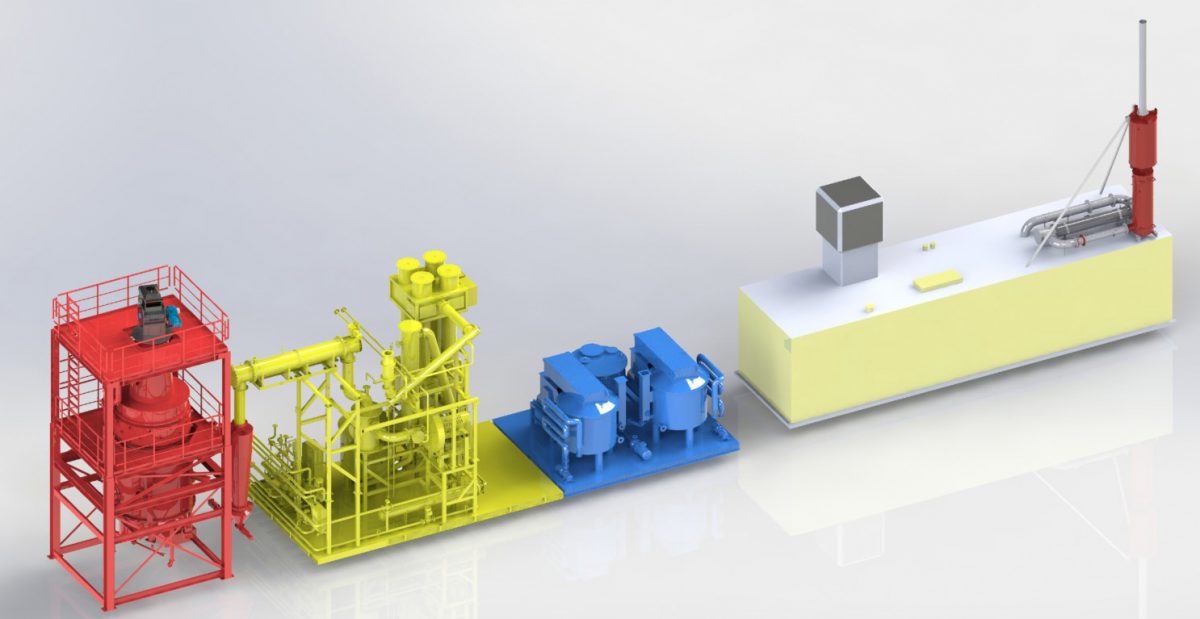

The high capacity of our briquetting lines ensure a high output and is ideal for industries with waste raw material from 2000 to 8000 tonnes per year. High profitability can be obtained through a combination of high capacity and low costs for raw material, along with controlled costs of labor and power.

The BP6510 is the mechanical briquette press with the highest capacity in the industry. The capacity is ensured through the double infeed system and control system. The briquette press is powerful and has the latest design. Furthermore, we can deliver technology with customized options with adapted saws and packaging lines, ranging from semi-industrial to automatic lines.

Most gasifiers require homogenous fuel as raw material with the correct amount of moisture and within a specific size. Many types of raw materials such as sawdust, other dust types, and smaller pieces of biomass are thus not suited for gasifiers, either because of their size or humidity level. However, turning this type of waste either from wood or agricultural waste into briquettes makes it possible to meet all requirements. Furthermore, it can add considerable value to the raw material, converting by-products into briquettes.

Our briquetting presses combined with other types of equipment like shredders, hammer mills, and drying systems can handle all types of dry and wet wood, as well as agricultural-based raw material, and turn it into high density briquettes for gasification.

Gasifiers require briquettes with high density, otherwise the fuel will disintegrate in the densifier. Our briquetting presses are able to produce high density briquettes out of most types of raw material due to our front-line technology.

The briquetting lines can produce industrial briquettes with diameters ranging from 50mm to 90mm, in different lengths from 20mm up to 100mm, and with densities between 1,1 and 1,2, making it the ideal fuel for gasifiers.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.