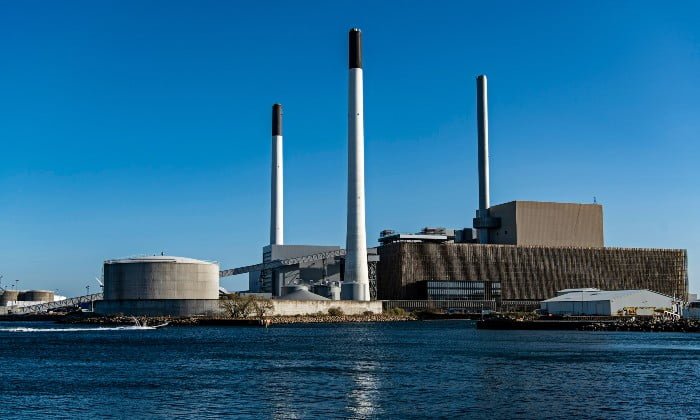

For more than 30 years, our briquette presses for industrial heat and power have been operating in Scandinavia. Over the years, the machines have been upgraded regularly to include the latest technology, resulting in higher capacities and lower costs per metric ton produced. The new technology has enabled us to enter new markets such as torrefied wood, which is believed to replace conventional coal within the years to come.

Recently, the concept has spread to other regions such as Eastern Europe, Africa and Asia, where the concept is being used along with local raw material – mainly agriculturally based – to generate heat and steam for industrial use.

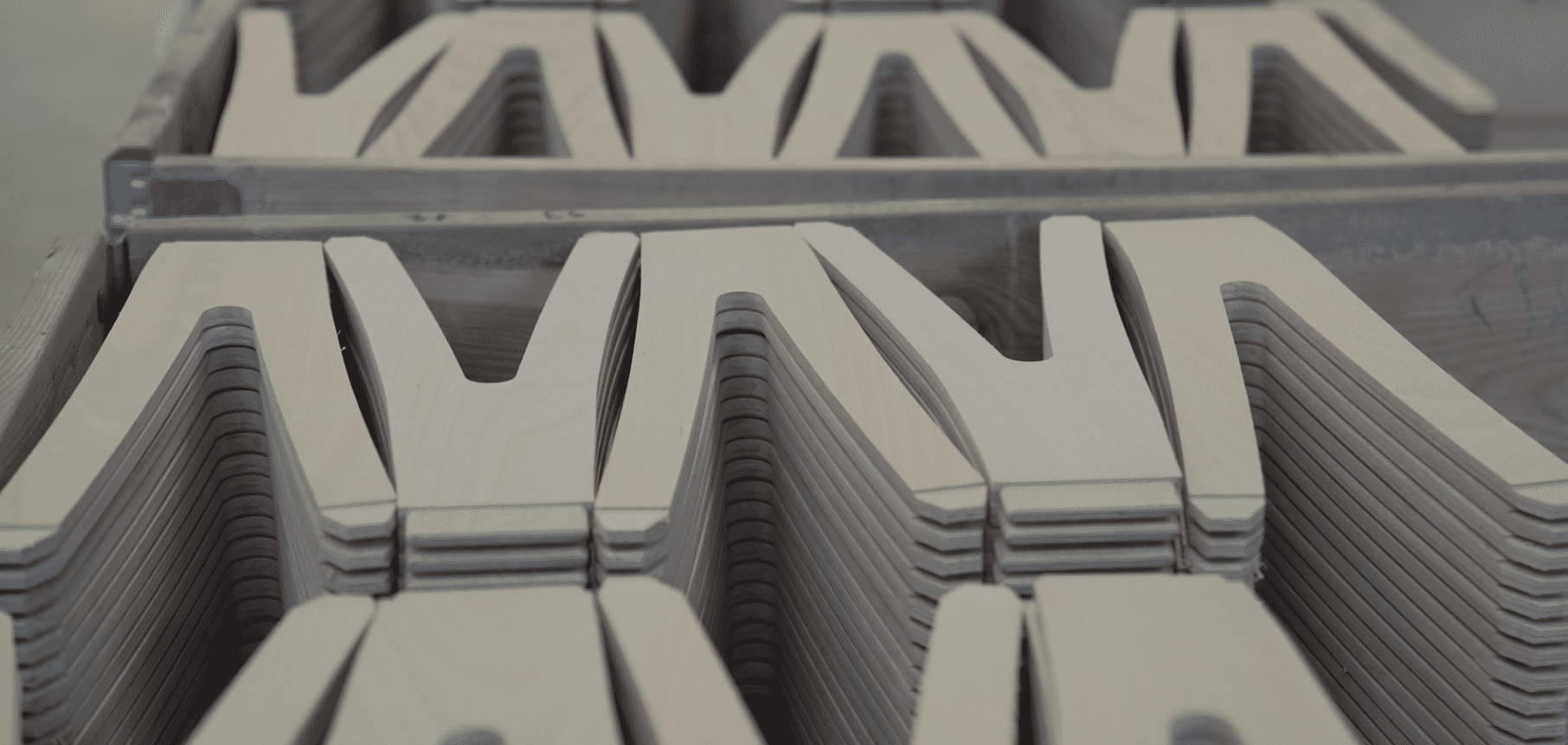

At C.F. Nielsen, we have specialized in mechanical briquette presses for industrial heat & power. With our unique solutions, difficult waste materials can be turned into valuable products. For a company with an annual waste from 500-50.000 tons, this is the ideal solution for a circular production.