1,3-1,5t/h Upgrading and expanding ...

Perssons Träteknik AB is a traditional Swedish wood ...

For over a century, Carl Hansen & Søn has been synonymous with high-quality furniture craftsmanship. As a third-generation furniture company, they have upheld the legacy of Danish design by preserving and producing timeless classics. With an unwavering commitment to quality, Carl Hansen & Søn seamlessly blends simplicity, aesthetics, and functionality in their creations, bringing iconic designs to life. Each piece exudes a sense of timelessness, reflecting the rich history of Danish design while also embodying modern sensibilities.

Carl Hansen & Søn A/S is located in the small town Gelsted on the Danish Island Funen.

As a furniture manufacturer, Carl Hansen & Søn produces 4-5 tons of wood residues daily. The wood residue was partly used in their own furnaces, but the majority of the residue was stored in silos and disposed of to local farmers, using 165 trucks every year to dispose of the waste material.

This was a strenuous task on both Carl Hansen & Søn and the environment, costing both money and unnecessary carbon emissions from the trucks. The company wanted to solve this task and teamed up with the local district heating facility in Gelsted. At first, Gelsted Fjernvarme purchased the residues as they were from Carl Hansen & Søn. However, due to a high level of dust – approximately 60-70% - the unprocessed material posed a significant risk due to the risk of dust explosions or fires. Therefore, the two companies began looking for another solution to get around the dangerous wood dust.

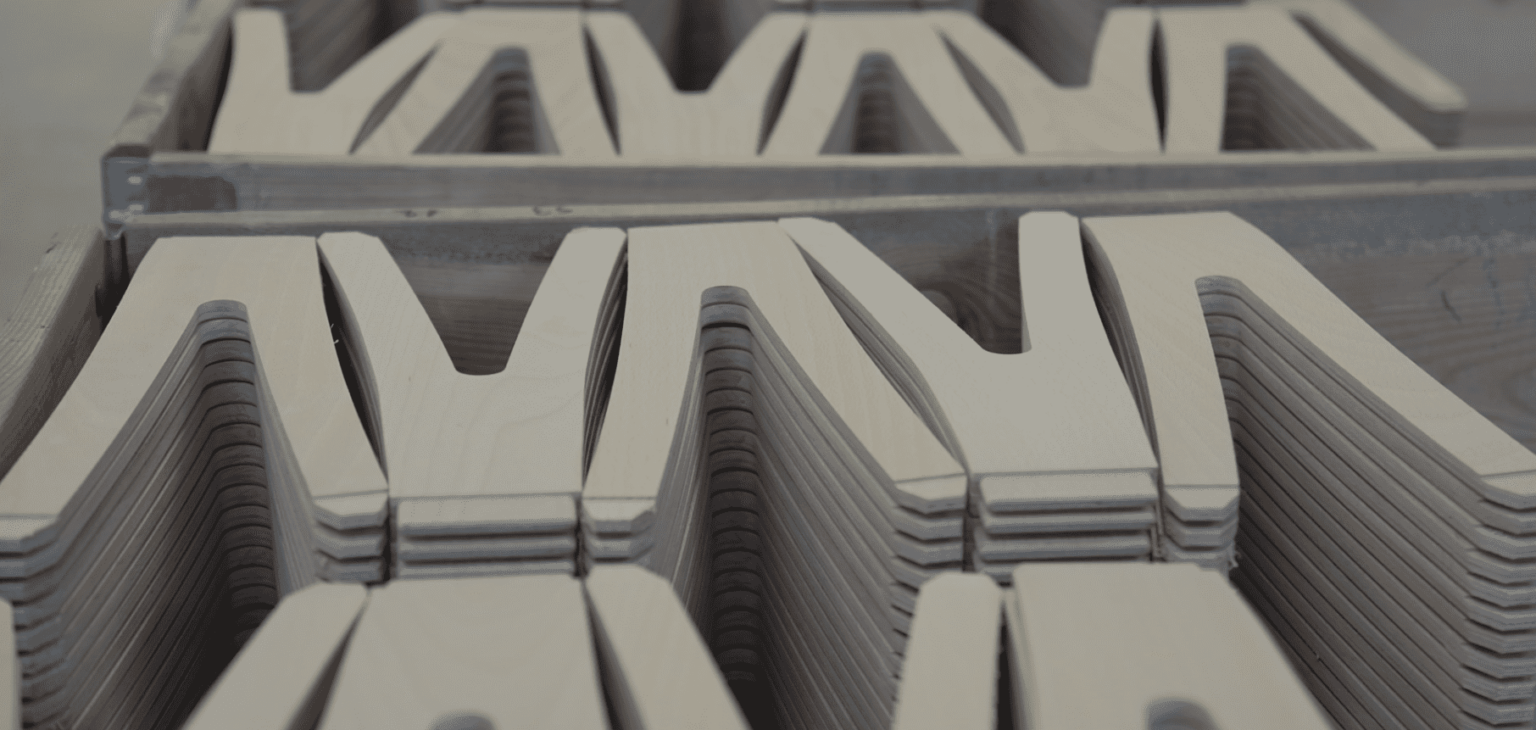

C.F. Nielsen was chosen to help solve the problem and create a more sustainable use of the wood residue without the risk of dust explosions. Gelsted Fjernvarme wanted to use the wood waste to create heat for the local residents. The ideal solution for both companies turned out to be briquetting machines in a newly built plant, turning the wood residue into briquettes. The briquette presses compress the wood residue from Carl Hansen & Søn into high-energy briquettes with a low moisture content, providing Gelsted Fjernvarme with a higher-caliber energy source and allowing them to store 5 times as much material in the same storage space. The collaboration between Carl Hansen & Søn and Gelsted Fjernvarme has also enabled Gelsted Fjernvarme to increase the number of houses that they deliver heat to.

With the effective briquetting machines from C. F. Nielsen, Carl Hansen & Søn were able to reduce their CO2 emission by 40%, and they expect their investment to be returned within 3-4 years. The Briquetting machine saves the furniture fabricant from keeping track of their waste and from ordering 165 trucks every year, drastically cutting the hours the administration team needs to organize the disposal of the wood residue. The investment in briquetting machines helped Carl Nielsen & Søn take a big step toward a more circular economy and at the same time save them both money and time.