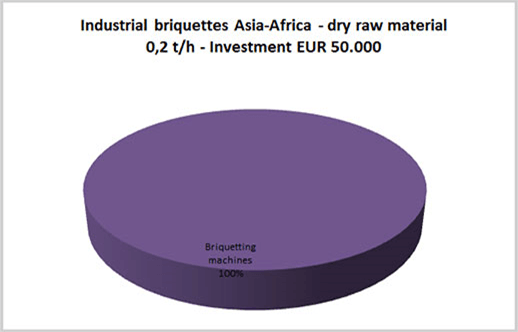

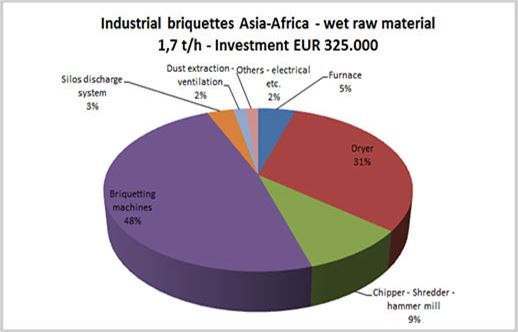

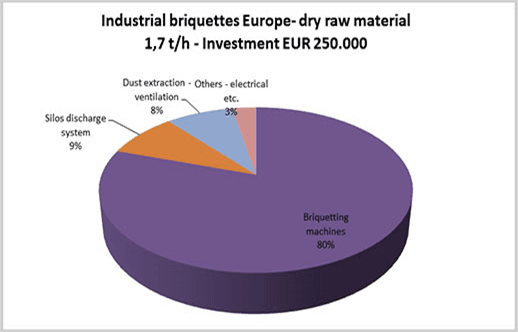

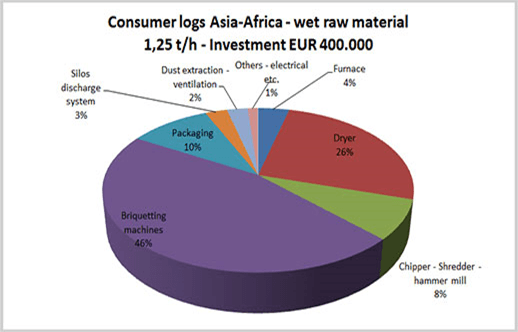

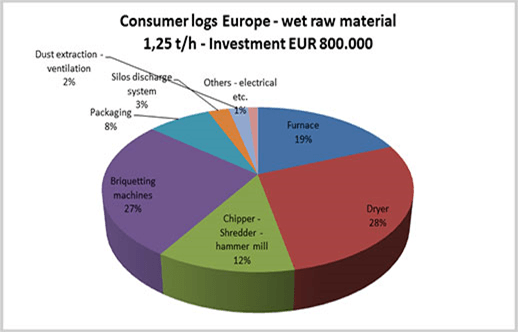

Many factors are influencing the price of a briquetting plant. Here are some of the most important ones:

Moisture level – Dry (below 14%) or wet (above 15%)?

Type of raw material?

Are you wondering whether your raw material can be used? Please click and see some of the raw materials other customers have used for making briquettes.

The briquetting press is the heart of the briquetting line and no compromise should be taken in terms of quality.

Having doubts regarding what type of briquetting system to chose? Take a look at the different briquetting machines.

Most agricultural crops are seasonal, unless the climate allows you to harvest crops several times a year.

The above examples and figures are estimated figures based on our experience in working in the different countries. As conditions, pricing etc. change all the time we ask you to consider the figures as examples only. In the end you should make your own calculations for your briquetting plant.

As you can see from the different examples, investment are generally higher in Northern Europe, due mainly to the high cost of labor, so most solutions are automatic. The margins are often lower, so the demand for efficiency is higher. Furthermore, safety measures are stricter and the demand for documentation higher. In other regions of the world like Africa and Asia where labor is cheaper many operations can be made manually and consequently the investments can be considerably lower.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.