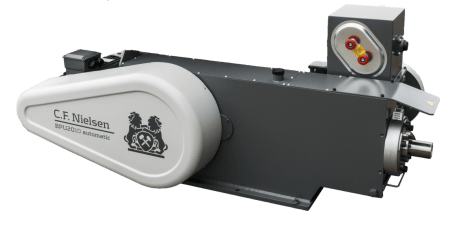

C.F. Nielsen has the worlds’ largest range of Mechanical briquetting presses ranging from 200 kg to more than 3.500 kg per hour. The presses are sold all over the world for different wood types, agriculture and other residues. Below you can see an overview of the different presses.

Esben M. Vestergaard

Regional Sales Manager

Do you want us to contact you?

Please fill out the form and we will get back to you.